When ordering a custom 3D print online, there are a number of options that most manufacturers will generally ask for, however not all of these options are common knowledge. By varying different elements of your print, you can either make more robust, strong pieces, or you can save time by cutting down on filament densities and details. In this post, we aim to go over the available options on our site to explain how to set up your print for the best balance of strength, performance, and cost!

Most on-demand 3D print providers will provide access to a number of similar settings. Some may be slightly different or called a different name, but the basics are pretty much the same across the board. The biggest options that you’ll run into when ordering a custom 3D print are “detail”, “material”, and “infill”. Let’s break these down in order to get a better understanding of how each one affects your final piece.

Balance Time and Clarity With Detail Settings

When you use our online tool, the first option you’ll be presented is a printer & detail selection option. We call this detail selection, but in reality, we’re actually adjusting certain printer parameters in order to achieve the specified detail. For example, it’s actually possible to print with different nozzle sizes on a 3D printer. The larger the nozzle, the faster the printer can deposit material, which means less over all time spent on the part. At the same time, however, a large nozzle is not very good at printing small, fine detail. For something like that, you actually want to use a smaller nozzle. As you can imagine, smaller nozzles will also take more time.

3D printers build objects by depositing material layer by layer, moving up slightly each time until the final shape is achieved. It’s possible to vary the height of these layers, which also has a direct affect on both time and quality. Taller layers mean lower detail in the final print, where smaller layers mean much more finely detailed pieces are possible.

For our printer detail presets, we offer a range of details. In general, the higher the detail, the smaller the nozzle and layer height we’re going to use for the print. That also results in a longer print time. Conversely, if you’re printing a larger object where detail isn’t quite as important, it’s generally better to choose a lower quality option, as we’ll use a larger nozzle and layer height on your part, which will drastically reduce time and cost of the finished part.

All of our custom print costs are based around machine time for any given filament, so the less time the piece takes, the cheaper it is!

Selecting the Best Material for Your Print

We offer a range of materials on our website that you can choose from, each with their own unique benefits. We have a page on the site that goes over all of our materials and their uses. It’s very recommended that if you’re new to 3D printing, you review this page to get a good idea of what each filament is recommended for.

Material selection ultimately affects the total cost of your print. Each material has its own hourly cost. Also, some materials have to be printed a bit more slowly than others. PLA is our cheapest filament option, great for small indoor decorative pieces, and pieces that won’t see much sun exposure or outdoor use. PETG is a step up from there in both cost and performance. If you’re looking for the best possible, highest strength filament you can get, our fiber infused PA (Nylon) options are the way to go. We also have a selection of specialty filaments such as metallic finishes, and TPU, a flexible plastic commonly used in phone cases.

Infill? What’s That?

When 3D printing, as mentioned previously, parts are built up in a layer by layer fashion. This offers some very unique mechanical advantages when compared to something like injection molding or subtractive manufacturing methods like CNC machining. With these traditional methods, the part ends up being completely solid as a part of the inherit design process. With injection molding, liquid material is pumped into a mold until it’s full, meaning there’s no space for the piece to be “hollow” at all. With machining / milling, you start with a solid block of material and cut away from it until you’re left with your final piece. Again, that piece is going to be solid as a result of the fact that you started with a solid block.

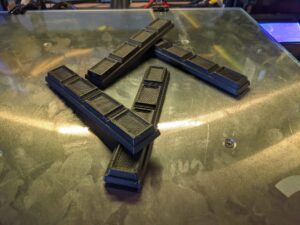

Since 3D printers build up material layer by layer, it’s actually possible for them to create semi-hollow objects. Rather than the inside of the part needing to be filled completely, it’s possible to configure the printer to build a grid structure of a particular density inside of the piece. This is known as infill. By choosing a lower infill amount, you’ll actually speed up the rate at which the printer can build pieces. Of course, lower infills trade off faster print times in exchange for lower durability. If you’re looking to make the strongest possible piece, you’ll want to choose 100% infill for a completely solid piece. If, however, you don’t have as high of strength requirements, you can go with a lower infill to save both time and cost. This is a very large advantage for cost savings over more traditional manufacturing methods.

What About Scale and Dimensions?

Some of our more attentive customers will notice that there are also options to adjust scale and dimensions. Dimensions will be set to either inches or millimeters, and will be determined by the person who originally created the file. If that’s you, make sure to choose your correct units. If it’s a file you got offline and it didn’t specify otherwise, then the units are likely in millimeters (mm).

Regarding scale, you really should be fine with standard 1.0x scale. This option is reserved for people who know they may want to build in a little extra tolerance to their pieces. Still, it may be best to make these mods in CAD software, but the option is there. Just be sure you know what you’re doing when you choose to use it!

Question? Our Team is Ready to Help!

If you’re trying to order a custom print and you’re still not sure what options are best for you, feel free to get in touch with us and we’d be happy to help. We’re available by phone or email seven days a week! You can get in touch with us via any of the methods on our contact page, and a member of our team will get back to you within 24 hours with more information. We can’t wait to help you bring your custom piece to life!